Tungsten Carbide Tools

We are good quality supplier of Tungsten Carbide Cutting Tools, Tungsten Carbide Inserts and Tungsten Carbide Dies from China.

Unveiling the Power of Tungsten Carbide Tools: Precision, Durability, and Performance

Tungsten carbide tools represent some of the most durable and versatile cutting and drilling implements used across various industries. Known for their exceptional hardness, strength, and heat resistance, tungsten carbide tools have become indispensable in machining, mining, construction, and numerous other applications where precision and endurance are paramount.

Tungsten carbide tools represent a pinnacle of engineering innovation, offering unmatched hardness, strength, and heat resistance across a myriad of industrial applications. As technology continues to advance, tungsten carbide remains at the forefront of cutting and drilling technologies, enabling greater efficiency, precision, and reliability in manufacturing and construction processes worldwide.

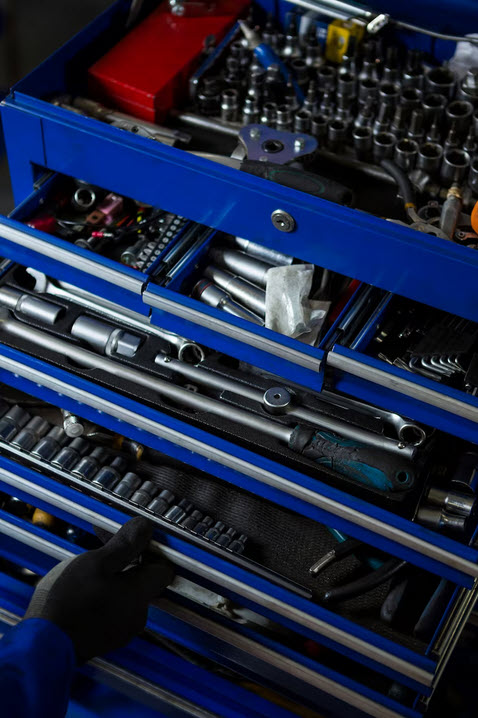

Tungsten carbide tools find applications in a wide range of industries and processes, including:

Metal Cutting and Machining

Tungsten carbide inserts, drills, end mills, and lathe tools are extensively used in metalworking operations such as milling, turning, drilling, and grinding. These tools offer superior cutting performance and longer tool life compared to traditional high-speed steel tools.

Mining and Rock Drilling

Tungsten carbide mining tools, including drill bits, inserts, and cutting picks, are employed in exploration, excavation, and tunneling operations. Their exceptional hardness and wear resistance make them ideal for drilling through hard rock formations and abrasive materials.

Woodworking

Tungsten carbide-tipped saw blades, router bits, and planer knives are popular in woodworking applications due to their ability to maintain sharp edges and withstand the abrasive nature of wood and composite materials.

Construction and Concrete Drilling

Tungsten carbide chisels, rotary hammer drill bits, and masonry drills are utilized in construction and demolition tasks involving concrete, brick, and stone. These tools offer efficient material removal and extended service life.

Automotive and Aerospace Industries

Tungsten carbide tools play a crucial role in manufacturing components for automotive engines, aircraft structures, and aerospace systems. Their precision and durability contribute to the production of high-quality parts with tight tolerances.

Cutting Through Challenges: Tungsten Carbide Tools at Work

Tungsten carbide is a compound comprised of tungsten (W) and carbon (C), usually in equal parts or varying ratios. It is produced through a powder metallurgy process where finely powdered tungsten and carbon are mixed, pressed, and then heated to high temperatures in the presence of a binder metal, typically cobalt or nickel. The resulting material is extremely hard and exhibits remarkable wear resistance.

The key properties of tungsten carbide tools include:

Hardness

Tungsten carbide is one of the hardest materials known, ranking very high on the Mohs scale of mineral hardness. This characteristic allows tungsten carbide tools to withstand substantial wear and abrasion, even in demanding machining environments.

Strength

Tungsten carbide tools possess exceptional compressive strength, making them capable of withstanding heavy loads and high pressures without deformation or breakage.

Heat Resistance

Tungsten carbide maintains its hardness and integrity even at elevated temperatures, which makes it suitable for high-speed machining operations where temperatures can rise significantly due to friction.

Chemical Inertness

Tungsten carbide is resistant to corrosion and oxidation, ensuring longevity and reliability in harsh operating conditions.